If you haven’t heard of Ultra backpack fabric, you may have been living under a rock. This revolutionary fabric is on the rise in the ultralight gear industry. It goes by the name Challenge Ultra, and it is making waves among cottage gear-makers as they discover its incredible strength, ultralight properties, and exceptional durability. Made from recycled material, Ultra boasts three times the tear strength and seven times greater abrasion resistance than its popular counterpart, Dyneema. While it may come at a slightly higher price, Ultra is being embraced by forward-thinking gear-makers as a potential replacement for Dyneema. So, if you’re in the market for a backpack that can withstand the toughest conditions while keeping your load ultra-light, Ultra fabric is definitely worth exploring.

Ultra Fabric: Introduction

Welcome to the world of ultralight backpacking! In recent years, there has been a significant buzz surrounding a revolutionary fabric called Ultra. This fabric has been making waves in the ultralight gear industry, catching the attention of backpackers and outdoor enthusiasts alike. In this article, we will explore the different aspects of Ultra fabric, its similarities to Dyneema, the benefits it offers, its strength and durability, its suitability for backpacks, its cost and availability, and the adoption of this fabric by cottage gear-makers.

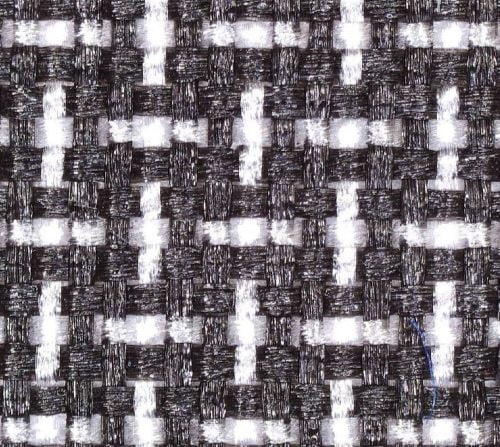

The revolutionary Ultra fabric sets a new standard for strength, durability, and waterproofing. Made with an ultra-high molecular weight polyethylene (UHMWPE) woven exterior and a laminated film backing, Ultra withstands the toughest demands. This groundbreaking fabric combines:

- Extreme tear and tensile strength

- Maximum abrasion and wear resistance

- Long-lasting, reliable waterproofing

Leading brands like Pa’lante Packs and LiteAF trust Ultra to help create their high-performance products. The 100D UHMWPE/polyester woven face, Ultra CrossPly yarn reinforcement, and recycled PET film backing work together to make Ultra the ideal choice when you need the lightest, strongest, and most durable waterproof fabric.

1. Ultra Fabric: Overview

What is Ultra Fabric?

Ultra fabric is a cutting-edge, recycled material that has quickly gained popularity among outdoor gear enthusiasts. Developed by cottage gear-makers, it combines the lightweight and technical properties of sailcloth with the durability needed for backpacking. This fabric is sourced from recycled materials, making it a sustainable choice for eco-conscious adventurers.

Ultra’s Similarities to Dyneema

Ultra fabric shares several similarities with the well-known Dyneema material. It offers a high strength-to-weight ratio, making it extremely durable despite its minimal weight. Both Ultra fabric and Dyneema are known for their exceptional tear strength and abrasion resistance, making them ideal for withstanding the rigors of outdoor activities.

Benefits of using Ultra Fabric

There are numerous benefits associated with Ultra fabric. Its impressive tear strength, seven times greater than Dyneema, ensures that your gear will withstand harsh conditions without compromising durability. Additionally, Ultra fabric offers seven times the abrasion resistance of the well-regarded Dyneema, guaranteeing a prolonged lifespan for your backpack. Its lightweight nature allows you to carry more essentials without adding unnecessary weight to your load. Overall, Ultra fabric presents a compelling option for those seeking a combination of lightweight performance and durability.

2. Ultra Fabric: Strength and Durability

Incredible Tear Strength

One of the standout features of Ultra fabric is its tear strength. With three times the tear strength of Dyneema, Ultra fabric provides unparalleled resilience against tears and punctures. This robustness ensures that your backpack will withstand sharp rocks, branches, and other potential hazards encountered on your outdoor adventures.

Abrasion Resistance

Ultra fabric excels in terms of its abrasion resistance as well. With seven times greater abrasion resistance than Dyneema, it minimizes the wear and tear caused by regular use and environmental factors. This enhanced durability ensures that your backpack will maintain its integrity and withstand the test of time, ensuring many adventures to come.

Ultra’s Strength Comparison to Dyneema

When comparing Ultra fabric to Dyneema, the key differentiator lies in the tear strength and abrasion resistance. While both materials offer impressive properties, Ultra fabric surpasses Dyneema in these aspects. However, it is important to note that Dyneema has its own unique strengths and may be more suitable for certain applications.

3. Ultra Fabric: Suitability for Backpacks

Ultra’s Weight vs. Strength

One of the primary considerations when selecting a backpack is finding the perfect balance between weight and strength. Ultra fabric strikes this balance exceptionally well. With its lightweight composition and remarkable tear strength, it allows you to carry essential gear without compromising on durability. This makes it an ideal choice for backpackers seeking a lightweight yet sturdy option.

Size and Capacity

Backpack size and capacity are crucial factors when planning outdoor adventures. Ultra fabric backpacks come in various sizes, ranging from daypacks to multi-day backpacks, catering to different trip durations and volumes of gear. The design and construction of Ultra fabric backpacks maximize internal space and organization, ensuring efficient packing and ease of access to your essential items.

Comfort and Ergonomics

In addition to strength and capacity, Ultra fabric backpacks prioritize comfort and ergonomics. These backpacks are designed with padded shoulder straps, adjustable sternum straps, and hip belts for optimal weight distribution and enhanced comfort during long hikes. The ergonomic design and thoughtful features allow you to carry your gear with ease, minimizing strain on your body and maximizing enjoyment of the great outdoors.

Current Ultra Fabric Options Available for Backpacks and Outdoor Gear

- Challenge Ultra 100 – Our lightest and strongest fabric at less than 3oz/yd2. With double the tear strength and nearly double the abrasion resistance of standard 500d Cordura, it sets the benchmark for ultralight performance.

- Challenge Ultra 200 – With a 200d Ultra PE exterior and recycled, waterproof RUV film backing, this 3.5oz fabric exceeds the technical specs of any comparable material. Durable and sustainable.

- Challenge Ultra 400 – Our 400d Ultra PE fabric is approximately 20% lighter yet 4x more abrasion resistant than other 400d UHMWPE materials. An extremely versatile high-strength pack fabric.

- Challenge Ultra 800 – By doubling the denier of our 400d fabric, Challenge Ultra 800 has the unmatched strength and durability for even the most demanding packs and duffels.

4. Ultra Fabric: Cost and Availability

Ultra Fabric Cost Comparison with Dyneema

It is important to consider the cost implications when selecting a fabric for your backpack. Ultra fabric, being a relatively new material, is priced slightly higher than Dyneema. However, the increased tear strength and abrasion resistance offered by Ultra fabric justifies its higher price point. The durability and longevity of an Ultra fabric backpack make it a wise investment for those seeking gear that will last for years to come.

Accessibility for Cottage Gear-Makers

One of the advantages of Ultra fabric is its accessibility for cottage gear-makers. These small-scale manufacturers often prioritize quality, innovation, and sustainability, which aligns perfectly with the attributes of Ultra fabric. The fabric is readily available to cottage gear-makers, enabling them to craft customized backpacks and gear that meet the unique requirements of outdoor enthusiasts.

Environmental Considerations

Ultra fabric’s recycled composition aligns with the growing demand for sustainable outdoor gear. By using recycled materials, Ultra fabric contributes to the reduction of waste and promotes a circular economy. It offers environmentally conscious backpackers the opportunity to enjoy their adventures while minimizing their ecological footprint.

5. Ultra Fabric: Adoption by Cottage Gear-Makers

Why Cottage Gear-Makers Embrace Ultra

Cottage gear-makers have rapidly embraced Ultra fabric due to its exceptional performance and sustainable attributes. This fabric allows them to create gear that balances lightweight design, durability, and sustainability – a trifecta that appeals to the knowledgeable and environmentally conscious customer base of cottage gear-makers.

Should you upgrade to a Challenge Ultra backpack? Absolutely!

If your current pack uses ripstop nylon, Robic nylon, Cordura nylon, or similar, upgrading to Ultra will substantially increase durability and/or cut weight, while keeping your gear dry thanks to the waterproof fabric.

For Dyneema users, the benefits are still worthwhile but less dramatic. Though Ultra edges out Dyneema in almost every lab test, real-world performance differences are modest. Dyneema remains excellent – lightweight, waterproof, and durable enough for most backpacking. With Ultra, you’ll get a bit more toughness and weight savings, more of a bonus than a game changer.

Either way, Challenge Ultra represents a top-tier fabric upgrade for new purchases or replacements.

Here is a summary of the key points about Ultra fabric from ultralight cottage manufacturers:

- Made with ultra high molecular weight polyethylene (UHMWPE), Ultra fabrics are extremely strong and abrasion resistant.

- Many cottage gear-makers have tested Ultra backpacks (and UltraTNT tarps) to assess durability claims.

- Key benefits observed:

- Very high tear strength

- Abrasion resistance

- Waterproofness

- Minimal stretch

- Potential downsides:

- Risk of delamination

- Less puncture resistance (UltraTNT)

- More noise/less compressible

- Higher cost

- Ultra seems extremely durable but some drawbacks exist. It may be overkill for less demanding users.

- Overall, Ultra delivers on strength and abrasion claims but comes with some tradeoffs.

Key Qualities of Ultra Fabrics:

- Extreme tear and tensile strength

- Maximum abrasion/wear resistance

- Waterproof

- Very limited stretch

- Noise/packability disadvantages

- Expensive

- Concerns about delamination

Testing New Fabrics for Knowledgeable Customers

Cottage gear-makers continuously strive to meet the evolving needs of their customers. By testing new fabrics like Ultra, they can gather insights and feedback from knowledgeable and experienced backpackers. This iterative process ensures that the gear produced meets the highest standards, providing customers with top-of-the-line equipment for their outdoor adventures.

Competitive Advantage and Differentiation

The adoption of Ultra fabric by cottage gear-makers provides them with a competitive advantage and differentiation in the ultralight gear industry. By offering cutting-edge gear made from Ultra fabric, these manufacturers attract outdoor enthusiasts seeking innovative, sustainable, and high-performance gear. This not only enhances their reputation but also positions them as leaders in the ultralight backpacking market.

In conclusion, Ultra fabric has emerged as a game-changer in the ultralight gear industry. With its remarkable tear strength, superior abrasion resistance, and sustainable attributes, it has become a sought-after material for backpacks. The adoption of Ultra fabric by cottage gear-makers further strengthens its position in the market and ensures that backpackers can enjoy lightweight yet durable gear for their outdoor pursuits. So, whether you are embarking on a weekend backpacking trip or a thru-hike, consider choosing an Ultra fabric backpack to experience the ultimate combination of performance, sustainability, and comfort. Happy trails!

This was a super informative read! I’ve been using Dyneema for years, but I’m genuinely intrigued by Ultra’s performance claims. Especially the abrasion resistance — that could make a huge difference on longer trips.

Still debating whether to switch from my current Robic-based pack. Ultra sounds promising, but I’m curious how it handles over several seasons of use and exposure.

“Delamination” caught my eye as a potential issue. Has anyone experienced that yet with the newer batches? Would love to hear real-world feedback before committing.